General Machining

At Stevens Grinding Company, we provide precision machining solutions that meet the highest industry standards. From large-scale material removal to ultra-fine finishing, our comprehensive range of grinding, cutting, and lapping services ensures accuracy, consistency, and quality every time. With advanced equipment, decades of expertise, and a dedication to customer satisfaction, we deliver results you can rely on — on time and to your exact specifications.

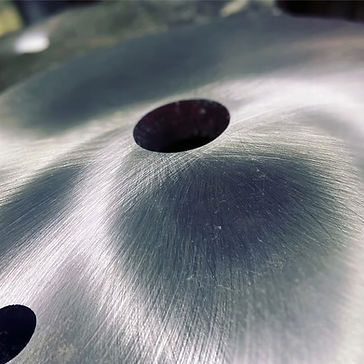

High-capacity rotary surface grinding for rapid, precise material removal on large workpieces. Perfect for castings, plate stock, and forgings, delivering consistent thickness, flatness, and tight tolerances with a signature crosshatch finish.

Simultaneous grinding on both sides for maximum accuracy, parallelism, and efficiency. Ideal for high-volume production of parts that require consistent thickness, smooth finishes, and reduced machining time.

Precision surface grinding for flat, smooth finishes and tight tolerances. Ideal for creating uniform thickness and refined surfaces on steel, aluminum, stainless steel, and specialty metals with consistent, repeatable quality.

Ultra-precise flat lapping for superior flatness, parallelism, and surface finish. Perfect for applications requiring extreme accuracy, consistent quality, and exceptional surface precision across a wide variety of materials.

High-accuracy saw cutting for steel, aluminum, and specialty metals. Capable of handling small to large stock sizes, reducing prep time for machining and improving efficiency.

Versatile water jet cutting for steel, aluminum, titanium, and specialty materials. Delivers clean, precise cuts without heat distortion, ideal for intricate shapes and complex designs.